Our Factories

WorkFar’s flagship humanoid robot, “Syntro”, along with our automation system integration components, and external customer manufactured products, are designed, engineered, and manufactured virtually entirely in-house at our advanced facilities across the United States. Equipped with CNC machining, plastic injection molding, tooling and fabrication, assembly, and end-to-end engineering capabilities, our U.S.-based factories enable rapid prototyping, scalable production, and seamless integration. Strategically located, we deliver high-performance technology solutions — from design and manufacturing to installation and support — both nationwide and globally.

ISO 9001:2015 Certified

Our Manufacturing Services

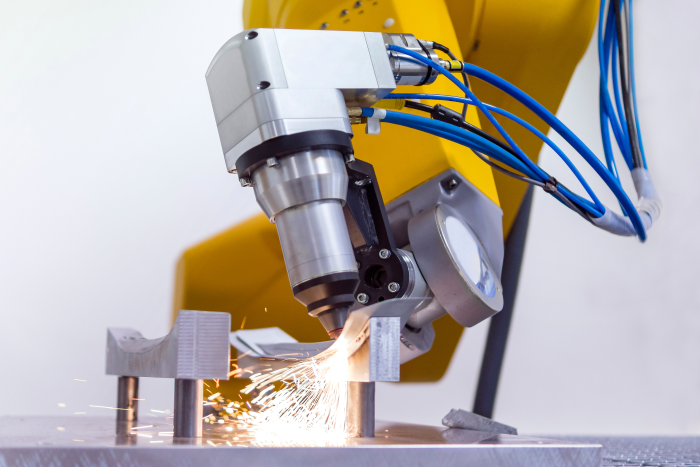

CNC Machining Services

We specialize in complex machined components and sub-assemblies, offering rapid, end-to-end manufacturing solutions for everything from new product development to high-mix/low- and high-volume production. Leveraging advanced technologies — including 5-axis CATIA programming, automated pallet systems, digital quoting, ERP scheduling, and model-based CMM inspection — we ensure precision, efficiency, and full SPC data control.

Fabrication and Sheet Metal

We specialize in high-precision aerospace metal fabrication, delivering certified components for both commercial and military aircraft using advanced techniques like CNC machining, laser cutting, stamping, and forming. Working with aerospace-grade metals and backed by industry certifications, we ensure unmatched durability, accuracy, and reliability for the most demanding applications.

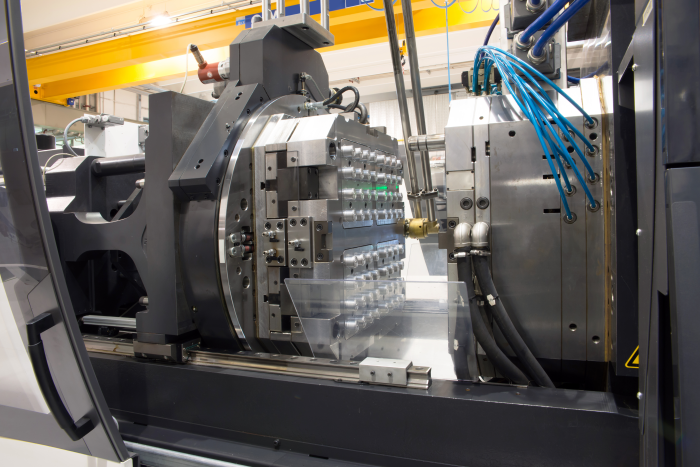

Plastic Injection

We offer a full range of injection molding services — including insert molding, overmolding, and hot runner systems — with support for short-run production using quick-change MUD inserts and a wide selection of engineering and commodity-grade plastics. From design and mold fabrication to final production, our streamlined, CAD-driven process ensures consistent, high-quality parts with minimal waste and optimal cost-efficiency.

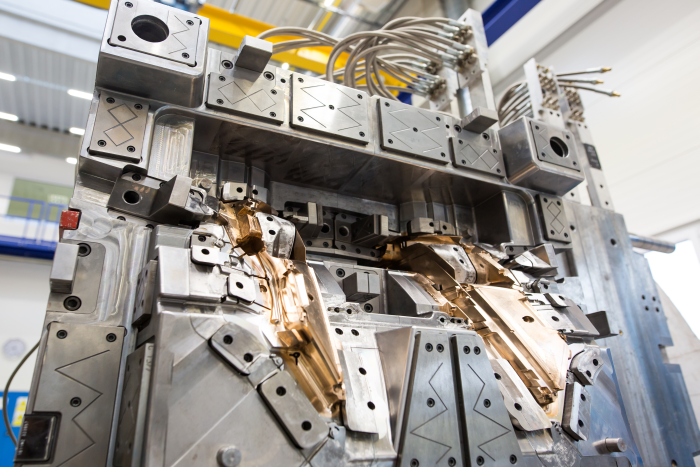

Mold and Tool Building

We design and fabricate nearly all of our injection molds and tooling in-house using advanced CNC and EDM equipment, ensuring full control over quality, speed, and cost. From Class 104 prototypes to Class 101 production molds, our U.S.-built tooling — including MUD modular inserts — enables rapid turnaround, precision performance, and unmatched agility.

Value Add Services

We provide value-added manufacturing services including in-house machining, PSA application, heat staking, full component assembly, and custom packaging, with the ability to design and build custom fixtures. Additionally, we also offer 3D printing, laser cutting, waterjet services, part decorating, labeling, and quality control for a complete end-to-end solution.